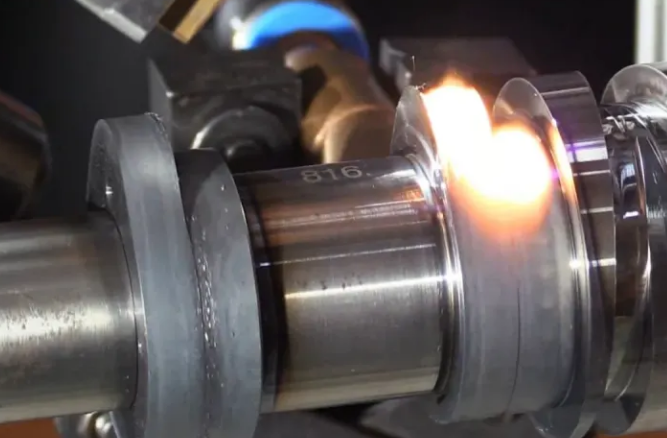

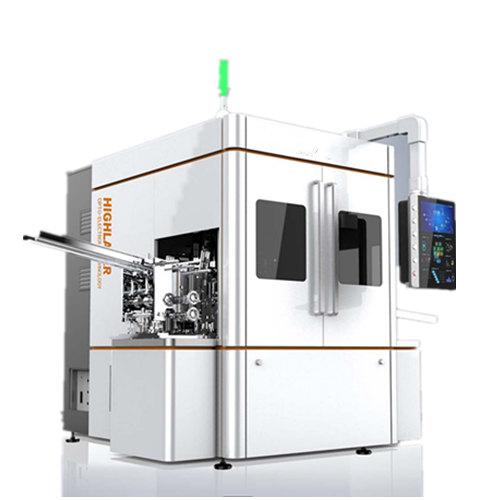

It is suitable for welding all kinds of KN95 mask machine welding knives, mask machine welding gear shafts, embossing rollers, embossing shafts, cross-cutting knife sticks, knife pillows, knife molds, folding mask machine molds, rolling die cutters, gear shafts , cam and other standard parts and non-standard parts customized laser quenching equipment. Suitable materials: Cr12MoV, DC53, SKD11, 40Cr, 42CrMo, medium carbon steel and other commonly used die materials. Email: joy@dumanlaser.com

Email Us

joy@dumanlaser.comContact Number

+86 18250801164 English

English русский

русский español

español 한국의

한국의

.jpg)

IPv6 network supported

IPv6 network supported